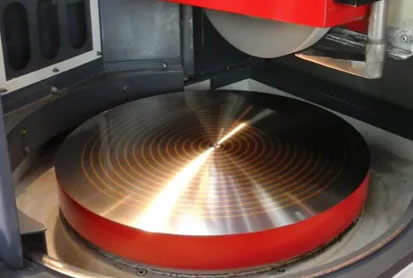

Rare earth permanent magnets have been developed and applied earlier. They take iron and iron group elements as an important part of alloy permanent magnet materials, also known as permanent magnet alloys, mainly including aluminum nickel cobalt permanent magnet alloys, iron chromium permanent magnet alloys and platinum cobalt permanent magnet alloys.

As an upgraded product of electromagnets and permanent magnets, although its cost is higher than that of electromagnets, many performance advantages of adjustable magnetic force can be completely superior to electromagnets only by cutting off the power supply without losing magnetism, which is also the main reason why more and more machinery manufacturers use lifting permanent magnets to carry workpieces. Then, in the workshop production, how to control the magnetic force and the size of the magnetic force of the lifting electric permanent magnet? Next, let's take you to understand.

Development and application of permanent magnets

As an upgraded product of electromagnet and permanent magnet, although the cost of permanent magnet of electromagnet is higher than that of electromagnet, it is only electromagnet (when electromagnet is used, it will suddenly cut off power and will not lose magnetism, and when lifting materials, the workpiece will not fall down due to sudden power failure. The safety factor is a qualitative leap). Because of some shortcomings, we have ideas and motivation to improve them. The expansion of every industry is a technology competition, and every new product is an industry adventure. Innovation is the driving force of development in contemporary society. Innovation is development, and innovation is the future. When it comes to scientific and technological innovation, the key is to rely on scientific and technological innovation to transform the driving force of development - people are inert, materials are inert. An ancient and normal way, a simple and extensive way of development, is unsustainable.

To sum up, compared with ordinary electromagnets, the safety factor of magnetoelectric lifting permanent magnet has made a qualitative leap, and it is currently a relatively safe and reliable environmental protection lifting equipment. If you are interested in lifting permanent magnets, please pay attention to us.

The sharp increase in the installed capacity of wind power has driven the demand for neodymium iron. With the increase of installed capacity of wind power generation, the permeability of permanent magnet direct drive generator has increased. The demand for Nd-Fe-B in wind power generation may reach tens of thousands of tons in 2025, several times that in 2019. Permanent magnet direct drive wind turbine will gradually replace doubly fed wind turbine and expand the application of high-performance Nd-Fe-B permanent magnet materials. Most direct drive wind turbines are permanent magnet synchronous generators. Due to the advantages of low maintenance cost and high system efficiency, there is a trend to gradually replace the double fed fan. High performance NdFeB magnetic materials are widely used in permanent magnet direct drive wind turbines. Improving the permeability will increase the market space of high-performance NdFeB magnetic materials.

Install the permanent magnet at the end of the truss robot or robot arm and send a short magnetic charging signal (about 0.01-2 seconds) to the permanent magnet, which is magnetic. At this time, the electric permanent magnet can absorb multiple workpieces at one time for handling. Compared with traditional handling, it improves the work efficiency, reduces the labor intensity of workers, and helps the workshop to develop towards automated production.

Current Location : Home > Product > Development and application of permanent magnets

Development and application of permanent magnets

time: 2022-6-26 10:31:37

Relevant News

-

Which manufacturers produce magnets

With the number of magnet manufacturers increasing year by year, it is difficult for customers to purchase wholesale powerful magnets. Where can I buy high-quality powerful NdFeB magnets? Which manufacturers produce magnets? Next, we recommend suitable Nd-Fe-B magnet manufacturers for your reference. MORE >2022

7-22

-

What are the types of strong NdFeB magnets

Powerful NdFeB magnets are often used in industry and life, but few people know the types and shapes of NdFeB magnets. Based on my years of experience, I'd like to share with you the relevant knowledge of NdFeB. MORE >2022

6-26

-

How much is the price of Shanghai powerful permanent magnet

Shanghai Qiangli permanent magnet manufacturer has the whole industrial chain of Nd-Fe-B magnet material blanks, finished magnet finishing, magnet surface electroplating treatment, etc MORE >2020

8-26

-

Price of sintered NdFeB magnets (h, SH, uh, eh Series)

Sintered NdFeB magnet brand 35h price 150-160 yuan / kg, 40SH price 260 yuan / kg, 35uh price 280/ kg, 38eh365-375 yuan / kg. MORE >2020

7-20

-

Can the magnetic pole of a permanent magnet be changed

Compared with the traditional excitation regulator generator set and motor, the permanent magnet generator has the characteristics of simple structure, small size, light weight, high efficiency, low temperature rise, low noise, convenient maintenance and so on MORE >2022

6-26

-

Development and application of permanent magnets

Rare earth permanent magnets have been developed and applied earlier. They take iron and iron group elements as an important part of alloy permanent magnet materials, also known as permanent magnet alloys, mainly including aluminum nickel cobalt permanent magnet alloys, iron chromium permanent magnet alloys and platinum cobalt permanent magnet alloys. MORE >2022

6-26

-

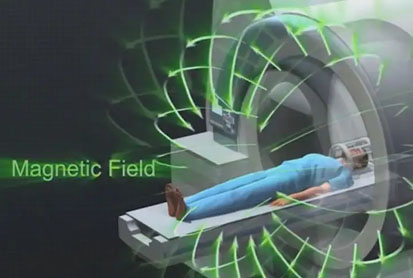

Progress in 3D ring magnetic resonance metamaterials

Electromagnetic field moment is usually covered by electric level moment and electromagnetic field moment due to poor tensile strength, which cannot be observed immediately MORE >2022

6-18

Recommended Products