Current Location : Home > Product > SmCo permanent magnet

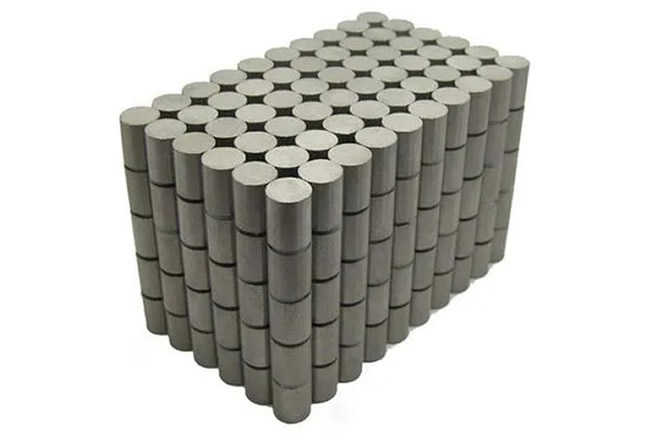

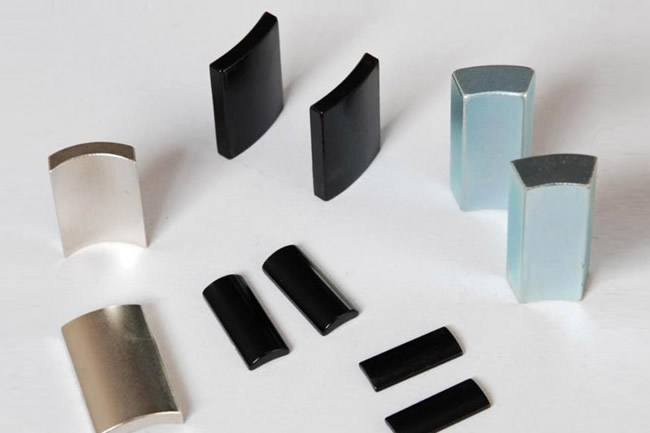

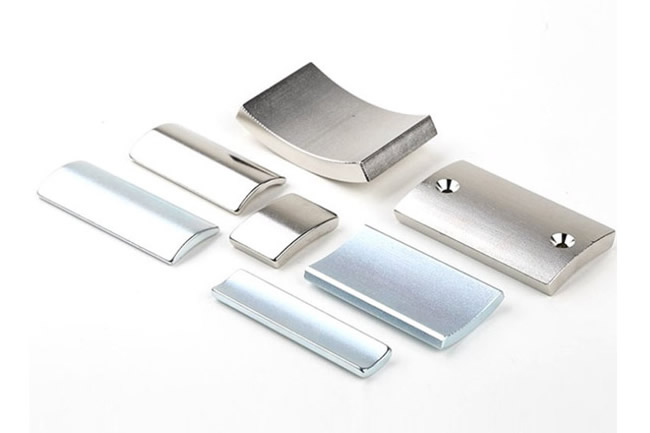

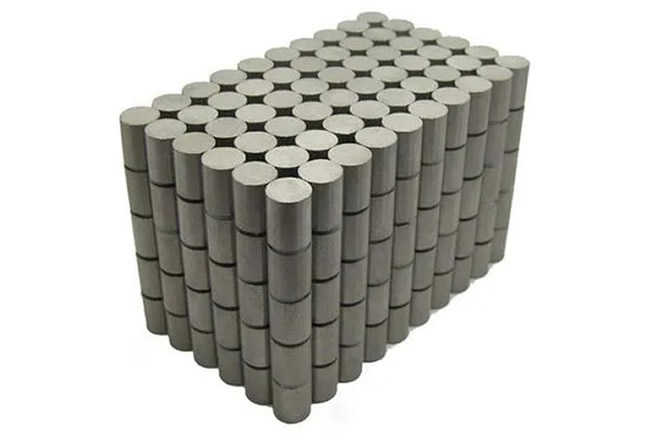

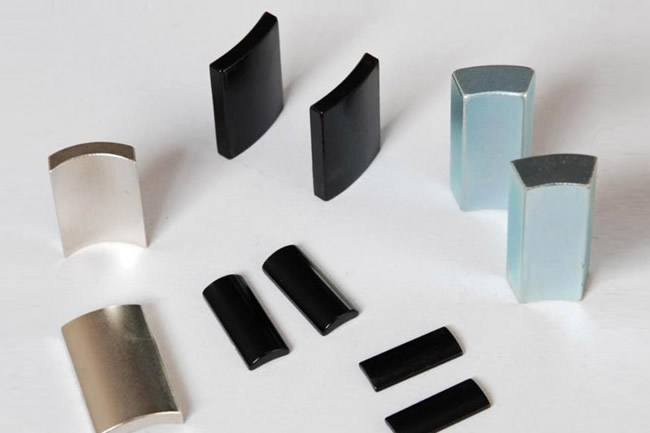

SmCo permanent magnet

- Manufacturer:

SHANGHAI SHEENSEN MAGNET

- Magnet price:

Large wholesale price is preferential

- Model and specification:

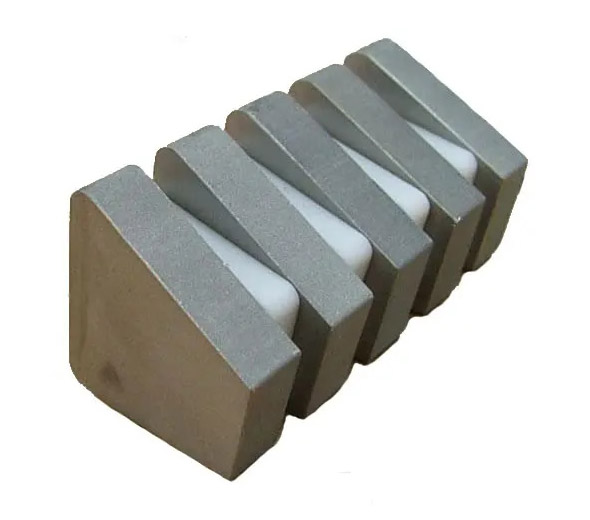

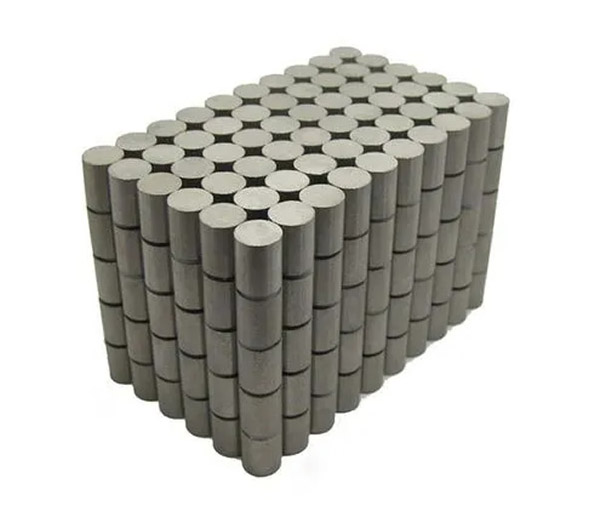

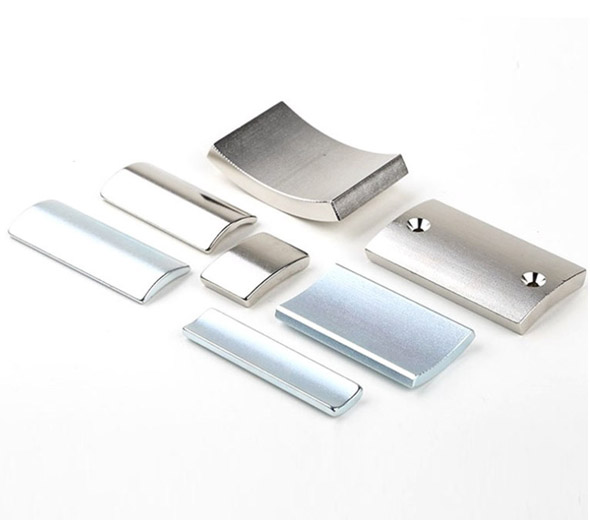

Support customization of any specification and size

- application area:

Motor field, mechanical equipment, medical care, electroacoustic field, electronic appliances, new energy, magnetic tools, etc

SmCo permanent magnet Details

SmCo Magnet is a kind of rare earth magnet, which is a kind of magnetic tool material made of samarium, cobalt and other metal rare earth materials after proportioning, melting and refining into alloy, crushing, molding and sintering. It has high magnetic energy product, low temperature coefficient, high working temperature of 250-350 ℃, unlimited negative temperature. When the working temperature is above 180 ℃, samarium cobalt permanent magnet has large magnetic energy product (BHmax) The coercivity, temperature stability and chemical stability are better than those of Nd-Fe-B permanent magnet materials, which have strong corrosion resistance and oxidation resistance.

Compared with neodymium iron boron magnets, SmCo Magnets are more suitable for working in high-temperature environments, and are very suitable for manufacturing all kinds of high-performance permanent magnet motors and application products with complex working environments. Therefore, they are widely used in aerospace, national defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes, etc. The large magnetic energy product (BHmax) of SmCo Magnets ranges from 16 mgoe to 32 mgoe. Samarium cobalt permanent magnets have two composition ratios, namely (samarium atom: cobalt atom) 1:5 and 2:17.

SmCo Magnet processing

Production process of SmCo Magnet: batching → smelting and ingoting → milling → molding → sintering and tempering → magnetic testing → grinding → pin cutting → finished products.

These alloys are usually processed in non magnetized state. Samarium cobalt is used for wet fine grinding (water-cooled heat dissipation) and diamond grinding wheel. This process is required if drilling holes or other functions are limited. Grinding waste must not be completely dry, because samarium cobalt has a low ignition point. A small spark, such as production with static electricity, can easily burn. The temperature caused by fire will be very high and difficult to control.

SmCo Magnet features

Samarium cobalt permanent magnets have very good coercivity and good temperature stability.

SmCo Magnets are expensive and vulnerable to price fluctuations (cobalt market is price sensitive).

SmCo Magnets peel easily. Goggles must be worn when handling them.

Striking the magnets together may cause the magnets to shatter, which may lead to potential danger.

Samarium cobalt is manufactured by a process called sintering, and all materials are sintered. Cracks are very likely to occur inside. The magnet has no mechanical integrity, only the function of preparing magnetic field. Therefore, special mechanical systems must be designed to give the overall system sufficient mechanical reliability.

Our advantages

1. Rich experience: we are a SmCo Magnet manufacturer engaged in permanent magnet materials for many years, and can provide you with one-stop customized solutions for powerful magnets.

2. Quality assurance: there are many magnet brands, models and specifications; After strict production process, complete testing, analysis, detection and test are equipped to ensure that customer needs are met.

3. Fast delivery: it has a number of production equipment to meet the production requirements of customers for permanent magnet materials; It can ensure product quality, deliver goods on schedule, and provide customized processing services.

4. After sales considerate: professional after-sales team and logistics distribution system provide you with one-to-one considerate service for processing and delivery.

We focus on the customized production and sales of SmCo Magnets. We can customize permanent magnets with any specification and performance. If you need to customize SmCo Magnets for quotation and proofing, you are welcome to come with pictures and samples.

Compared with neodymium iron boron magnets, SmCo Magnets are more suitable for working in high-temperature environments, and are very suitable for manufacturing all kinds of high-performance permanent magnet motors and application products with complex working environments. Therefore, they are widely used in aerospace, national defense and military industry, microwave devices, communications, medical equipment, instruments, meters, various magnetic transmission devices, sensors, magnetic processors, motors, magnetic cranes, etc. The large magnetic energy product (BHmax) of SmCo Magnets ranges from 16 mgoe to 32 mgoe. Samarium cobalt permanent magnets have two composition ratios, namely (samarium atom: cobalt atom) 1:5 and 2:17.

SmCo Magnet processing

Production process of SmCo Magnet: batching → smelting and ingoting → milling → molding → sintering and tempering → magnetic testing → grinding → pin cutting → finished products.

These alloys are usually processed in non magnetized state. Samarium cobalt is used for wet fine grinding (water-cooled heat dissipation) and diamond grinding wheel. This process is required if drilling holes or other functions are limited. Grinding waste must not be completely dry, because samarium cobalt has a low ignition point. A small spark, such as production with static electricity, can easily burn. The temperature caused by fire will be very high and difficult to control.

SmCo Magnet features

Samarium cobalt permanent magnets have very good coercivity and good temperature stability.

SmCo Magnets are expensive and vulnerable to price fluctuations (cobalt market is price sensitive).

SmCo Magnets peel easily. Goggles must be worn when handling them.

Striking the magnets together may cause the magnets to shatter, which may lead to potential danger.

Samarium cobalt is manufactured by a process called sintering, and all materials are sintered. Cracks are very likely to occur inside. The magnet has no mechanical integrity, only the function of preparing magnetic field. Therefore, special mechanical systems must be designed to give the overall system sufficient mechanical reliability.

Our advantages

1. Rich experience: we are a SmCo Magnet manufacturer engaged in permanent magnet materials for many years, and can provide you with one-stop customized solutions for powerful magnets.

2. Quality assurance: there are many magnet brands, models and specifications; After strict production process, complete testing, analysis, detection and test are equipped to ensure that customer needs are met.

3. Fast delivery: it has a number of production equipment to meet the production requirements of customers for permanent magnet materials; It can ensure product quality, deliver goods on schedule, and provide customized processing services.

4. After sales considerate: professional after-sales team and logistics distribution system provide you with one-to-one considerate service for processing and delivery.

We focus on the customized production and sales of SmCo Magnets. We can customize permanent magnets with any specification and performance. If you need to customize SmCo Magnets for quotation and proofing, you are welcome to come with pictures and samples.