Current Location : Home > Product > Heteromorphic NdFeB magnet

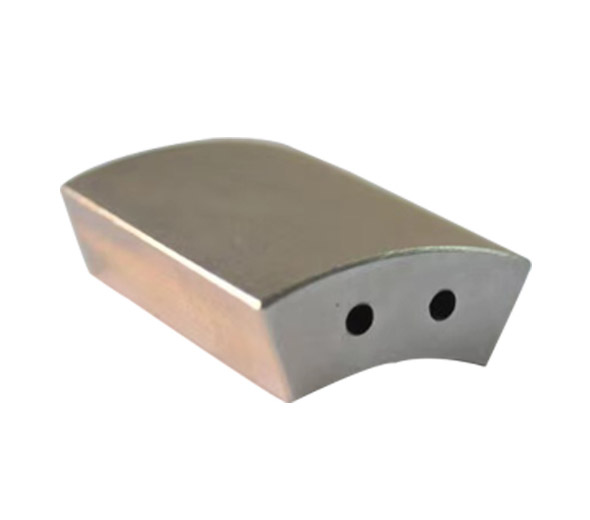

Heteromorphic NdFeB magnet

- Manufacturer:

SHANGHAI SHEENSEN MAGNET

- Magnet price:

Large wholesale price is preferential

- Model and specification:

Support customization of any specification and size

- application area:

Motor field, mechanical equipment, medical care, electroacoustic field, electronic appliances, new energy, magnetic tools, etc

Heteromorphic NdFeB magnet Details

Special shaped magnets refer to magnets with irregular shapes, which mainly serve specific needs. Injection molded magnets are very suitable for special-shaped magnets, but the large energy product (BH) max of conventional isotropic injection molded NdFeB magnets is limited to 60kj/m3, which cannot meet the needs of most special-shaped magnets.

Shaped magnet

1. The special-shaped magnet material is made of praseodymium, neodymium, pure iron, ferroboron and some metal elements in a certain proportion through multiple processes.

2. Nd-Fe-B is subdivided into sintered Nd-Fe-B and bonded Nd-Fe-B. sintered Nd-Fe-B magnets are commonly known as strong magnets or permanent magnets, because the magnetic properties of sintered Nd-Fe-B magnets are far better than bonded Nd-Fe-B magnets.

3. Preparation process: batching - smelting - pulverizing - molding - sintering (sintered Nd-Fe-B) - processing - magnetization to make finished products. The processing process includes: grinding, slicing, wire cutting, drilling, casing, electroplating, etc.

4. The surface treatment of arc-shaped Nd-Fe-B magnets is common, including zinc plating, nickel plating, nickel plating, copper nickel, epoxy resin, electrophoresis, gold plating, etc.

Special magnet characteristics

1. The magnetic force of the special-shaped magnet is strong, durable and has strong bearing capacity. It can absorb objects several times larger than its own volume.

2. Environmental friendly material, stable magnetic force and strong corrosion resistance. Generally, it can pass the salt spray test for 96 hours.

3. High and low temperature resistance, using high-quality rare earth neodymium iron boron, ferrite and other materials, -50 ° C to 260 ° c various temperature configurations are optional.

Our advantages

1. Rich experience: we are a manufacturer of countersunk hole magnets engaged in permanent magnet materials for many years, and can provide you with one-stop customized solutions for sintered NdFeB powerful magnets.

2. Quality assurance: there are many brands, models and specifications of special-shaped magnets; After strict production process, complete testing, analysis, detection and test are equipped to ensure that customer needs are met.

3. Fast delivery: it has a number of production equipment to meet the production requirements of customers for permanent magnet materials; It can ensure product quality, deliver goods on schedule, and provide customized processing services.

4. After sales considerate: professional after-sales team and logistics distribution system provide you with one-to-one considerate service for processing and delivery.

Shaped magnet

1. The special-shaped magnet material is made of praseodymium, neodymium, pure iron, ferroboron and some metal elements in a certain proportion through multiple processes.

2. Nd-Fe-B is subdivided into sintered Nd-Fe-B and bonded Nd-Fe-B. sintered Nd-Fe-B magnets are commonly known as strong magnets or permanent magnets, because the magnetic properties of sintered Nd-Fe-B magnets are far better than bonded Nd-Fe-B magnets.

3. Preparation process: batching - smelting - pulverizing - molding - sintering (sintered Nd-Fe-B) - processing - magnetization to make finished products. The processing process includes: grinding, slicing, wire cutting, drilling, casing, electroplating, etc.

4. The surface treatment of arc-shaped Nd-Fe-B magnets is common, including zinc plating, nickel plating, nickel plating, copper nickel, epoxy resin, electrophoresis, gold plating, etc.

Special magnet characteristics

1. The magnetic force of the special-shaped magnet is strong, durable and has strong bearing capacity. It can absorb objects several times larger than its own volume.

2. Environmental friendly material, stable magnetic force and strong corrosion resistance. Generally, it can pass the salt spray test for 96 hours.

3. High and low temperature resistance, using high-quality rare earth neodymium iron boron, ferrite and other materials, -50 ° C to 260 ° c various temperature configurations are optional.

Our advantages

1. Rich experience: we are a manufacturer of countersunk hole magnets engaged in permanent magnet materials for many years, and can provide you with one-stop customized solutions for sintered NdFeB powerful magnets.

2. Quality assurance: there are many brands, models and specifications of special-shaped magnets; After strict production process, complete testing, analysis, detection and test are equipped to ensure that customer needs are met.

3. Fast delivery: it has a number of production equipment to meet the production requirements of customers for permanent magnet materials; It can ensure product quality, deliver goods on schedule, and provide customized processing services.

4. After sales considerate: professional after-sales team and logistics distribution system provide you with one-to-one considerate service for processing and delivery.